In addition to a thorough internal assessment and product brief, there is another key element that will greatly benefit your product quality as well as the ROI of your branding project, namely, the request for a prototype before starting series production. This is an essential step that is still overlooked by many marketing professionals, even though it provides the ultimate means for maintaining full control of your branding plan and budget. Indeed, adding a prototyping phase will extend the project’s time frame by a number of weeks. But what if we were to tell you that having a prototype will prevent you from exceeding your budget and spending thousands of dollars unnecessarily?

This blog explains why a prototype is definitely worth the investment. First, let’s take a look at 3 major advantages of requesting a prototype.

I. A prototype ensures the delivery of premium products

Requesting a prototype before commencing series production is an ideal way to visually examine (and approve) your product’s appearance and quality. This step will afford you a valuable opportunity to check whether the product matches the design as well as your brand identity. It will also save you the unpleasant surprise of discovering that your product series actually deviates from the design. But most importantly, conducting a prototype inspection will ensure that you deliver premium trade marketing items that you fully endorse!

Pro tip: Never settle for a prototype with which you’re not completely satisfied. Curious to learn which elements require extra attention? And when to ask for a new sample? Download our practical guide and get useful advice on how best to inspect your prototype.

II. A prototype could save you hundreds of thousands of dollars

Would you rather spend an extra 500 dollars on a prototype or a huge sum of money on a duplicated production process? A prototype inspection will result in high-quality products rolling off the belt. It will also eliminate the risk of having to spend hundreds of thousands of dollars on reproducing your branding items due to unforeseen deviations or defects, not to mention the expenses associated with managing significant delays and unhappy stakeholders. By setting aside a few hundred dollars for the creation of a prototype and adding an extra four weeks to your project planning, you’ll always be on the safe side and you’ll have full control of your project.

Curious as to how valuable a prototype can actually be? Our practical guide contains a representative calculation.

A prototype keeps you in control of your project and guarantees the delivery of a premium product.

III. A prototype serves as a point of reference

Your prototype will also come in very useful later on in the trade marketing process. Once your first series of trade marketing items have been manufactured, you can ask your supplier to send you a single item from the very first series. This will give you the chance to inspect the final product you’ve been working on for so long. And what better way to check your branding items than to compare them to your approved prototype? Now, you can rest assured that your customers will receive only high-quality branding products.

Is your supplier able to produce a prototype?

Though it may be an important component of branding item development, not every supplier is able to produce a prototype. You may choose to hire an external party in this case. Nevertheless, it is much more beneficial to work with an experienced supplier who can offer the full package, from design to prototyping right up to manufacturing. In our practical guide, you’ll discover how creating a prototype guarantee both the feasibility and the quality of your products and satisfies sustainability and ethical demands throughout the branding process - all while maintaining a healthy budget.

The prototyping process at Dekkers

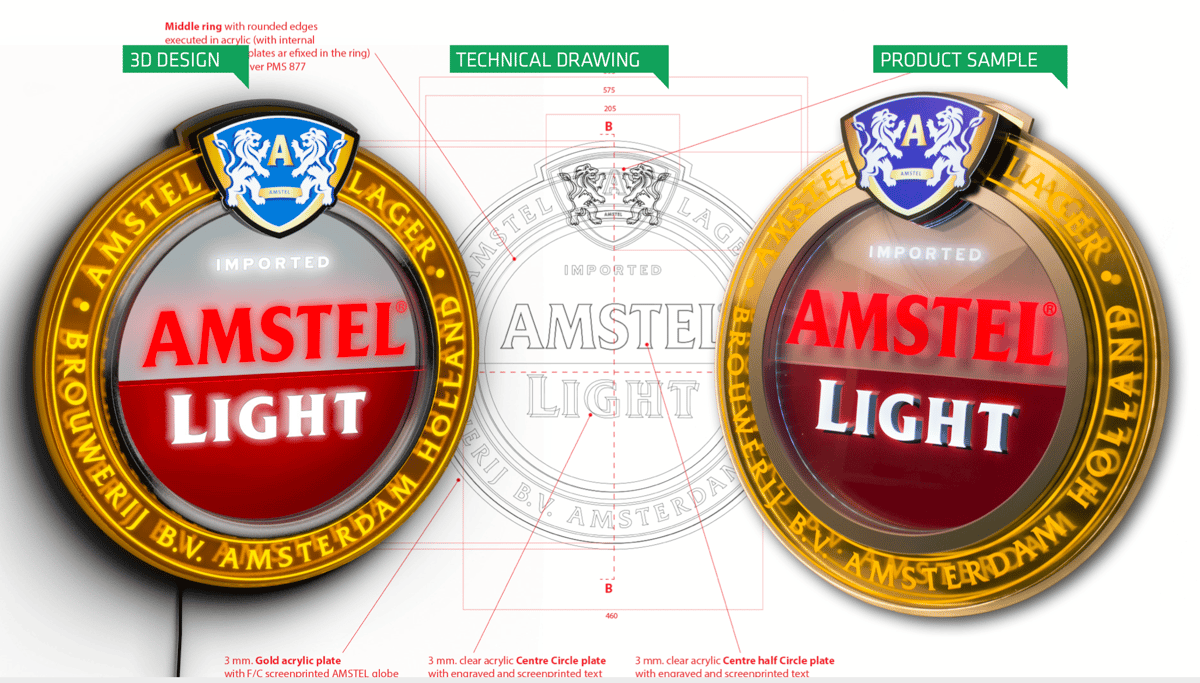

Dekkers International handles the full range of activities in the trade marketing process. Our top priority is to provide you with high-quality products. That’s why we devise 100% custom-made prototypes - so you can critically audit your product before manufacturing. To provide you with a state-of-the-art, high-quality product, prototype fabrication at Dekkers International is always preceded by the following process:

- A detailed technical drawing including all product specifications is provided by our tech-savvy design team. This drawing is subjected to a second internal evaluation before approval.

- An additional briefing takes place between the project manager and the engineers before commencing production. They also closely monitor and record the production process.

- During manufacture, your prototype is subjected to a careful visual and technical inspection by our on-site quality manager. This procedure is repeated by our Quality Assurance Manager upon arrival at our headquarters in the Netherlands.

- Once your prototype has been fully visually and technically approved, we make sure it is delivered to your doorstep for your final check!

To provide full transparency, every step of the procedure outlined above is extensively logged. Thanks to this and the application of a Four-Eye Principle during an inspection, you can rest assured that your prototype complies with all quality and safety conditions. This means that you can dedicate yourself entirely to judging the product on the basis of its consistency with your brand guidelines.

Our Quality Assurance Manager subjects every prototype to careful visual and technical inspection

Curious as to which other phases of the trade marketing process we can help you with? Our practical guide provides extensive, detailed coverage of every stage.

.png?width=600&name=Untitled%20design%20(4).png)